10 Common Problems with Ipe Decking

2. The Boards are Different Colors

It’s time to layout the 10 common consumer complaints and concerns about Ipe Decking. What are the fixes? Which ones are myths? And how to determine if Ipe is right for your deck project? This article will put the kibosh on all unanswered concerns and speculation. Read on to learn the truth about these common Ipe Decking problems.

1 . Ipe Is Too Hard

Ipe is, undoubtedly, one of the hardest woods in the world. There are harder species of wood, but not many. A Janka Hardness scale is used to measure and compare materials based on their hardness. Most reliable sources place Ipe in the top 10 of hardest woods. Of the top 10, Ipe is one of only three or four that are commercially available.

To put Ipe’s hardness in perspective, Ipe earns a Janka Rating of about 3,684. Compare that to White Oak, a domestic hardwood known for its hardness, at about 1200. Hardness is important to a materials longevity and durability. The benefits of being one of the hardest woods in the world are numerous. A high hardness rating lends to incredible longevity, durability and resistance to insects, fire, moisture penetration, mold and rot.

But, wait! Doesn’t Ipe’s hardness negatively affect its workability? Won’t I need special blades to cut it? Isn’t it too strong to straighten curves in the boards? The short answer; no, no, and no. But there are some tips that can make working with Ipe much easier,

- Special blades are not required to cut through Ipe. Standard chop saw blades work just fine on Ipe. However, it is highly recommended to use blades with carbide tips. In our experience, the number of teeth or the configuration of teeth, do not matter. Of course, using a jig saw or Sawzall will require a bit more effort, but these tools aren’t often used on decking projects. Contractors that use Ipe regularly know that sawing through harder wood simply takes longer.

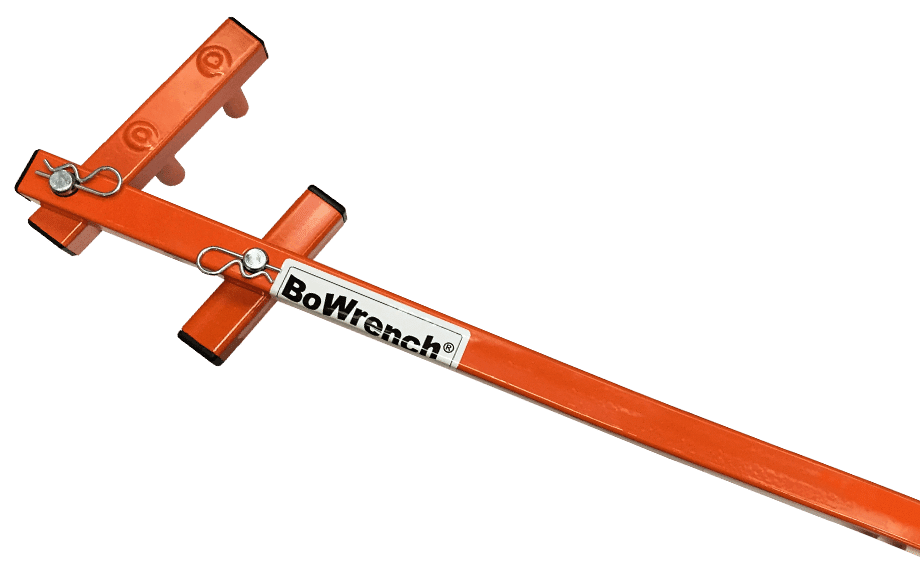

- Ipe is a product of nature. Like all natural woods, not every board can be perfectly straight. The solution is a tool called, the Bowrench. Made by Cepco tool company, most suppliers of Ipe are happy to sell you this tool for around $60-70. Many contractors that use Ipe, own Bowrenches. This tool grabs the joist and uses leverage to straighten the boards so they can be fastened easily. It’s also very effective with T&G applications. Be sure to purchase the extension if your deck is framed with double joists.

2 . The Boards are Different Colors

Some customers are unsure what to expect from Ipe, in terms of color. Manufactured decking boards, like plastics and composites, are not only consistent, they are EXACTLY the same. Real, Natural Wood, like Ipe, provides a variety of different colors, from light olive browns, to darker chocolate browns. This color variation is exactly what makes Ipe very desirable. It makes the deck look natural and gives it abundant character. Customers should also expect to find cathedral arches, interlocked grain patterns, and intermittent black striping. All of these features give Ipe it’s characteristic beauty. Here are some tips regarding color expectations,

- Most suppliers are happy to send free samples. Ask for samples that vary in color.

- Be sure that the Ipe is Premium Grade. Non-premium grade Ipe can have bug holes, knots and sapwood. Also, non-premium grade Ipe often varies in dimensions which makes them very difficult to use.

- Look at the suppliers Gallery. This should give you a good idea of what to expect from that supplier.

- Board color variation makes board replacement possible. Read more about this in problem number 5.

Other Brazilian Hardwood Species offer different colors and more consistency. Consider Garapa and Massaranduba for consistency in color.

3 . Ipe and Acclimation

Acclimation is the process of becoming accustomed to a new climate or new conditions. This is an oft overlooked or improperly addressed process for Ipe Decking installation. It applies to nearly all wood decking and flooring. If you are ordering Ipe, locally, this section probably doesn’t apply to you. But let’s say you live in Colorado and you ordered Ipe from Brazilian Wood Depot, in Atlanta GA. You will absolutely want to take heed of these simple tips,

- As usual, make sure you are purchasing Premium Grade Ipe. Anything less can result in lower performance.

- After receiving your shipment, leave the boards on the jobsite, outdoors for 10-14 days until the moisture level remains constant.

- If the boards will not be installed for a prolonged period of time, be sure to take a couple extra precautions;

- Place spacers in between the rows to allow air movement between the boards. Suppliers can often provide these upon request.

- Cover the materials, loosely, with plastic or tarp. Do NOT enclose the plastic such that it traps the air inside. Air should be able to move freely, in and out.

Ask the supplier for Storage and Handling tips.

4 . Ipe Requires Too Much Maintenance

Technically, Ipe doesn’t require any maintenance whatsoever. Ipe maintenance is only required to maintain the natural brown colors. Without maintaining an annual oil regimen, the boards will turn a beautiful silvery-grey. This will not affect the structural integrity, longevity, or durability of the wood. It’s all a matter of appearance. In fact, many customers prefer to let their Ipe go grey. The best part is, you can always bring them back to their original brown colors.

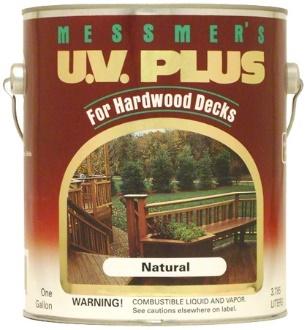

The general rule of thumb to maintain Ipe’s beautiful brown colors is an annual application of a UV Oil, with Messmer’s UV Plus, and periodic cleaning depending on conditions. Some customers are put off by the maintenance associated with Ipe. What they may fail to realize is that, the ability to refinish Ipe decks actually makes it a much more desirable decking material. Plastic and Composite alternatives fade overtime and cannot be brought back to the original conditions. Here are a few tips regarding oiling and maintenance,

- Don’t oil the boards before installation. It’s unnecessary and you may want to bump some spots with a sander which will require you to reoil.

- Don’t oil the bottom of the boards unless you plan on seeing them from below. Many customers ask if they need to oil the bottom. The answer is, no. Again, oil is only meant to protect against UV and maintain the color.

- Messmer’s UV Plus Natural is the best oil to use on Ipe. There are other products that will suffice, but Messmer’s is tried and true in performance and aesthetic.

- Messmer’s also makes a very effective Deck Cleaner and Brightener. You can also find Behr, All-in-One Wood Cleaner and Flood Deck cleaner at the big box hardware stores.

- For more tips on cleaning and oiling Ipe decks, visit or watch the video below.

5 . Damaged Board Replacement

This aspect of choosing a decking material is probably the most often overlooked. While Ipe is the most durable material decking option, they can still get damaged. The two most common ways decking boards get damaged is by spilling the hot contents of a grill or firepit and scratches from heavy metal furniture. Both of these can be remedied by replacing the boards. With Ipe, board replacement is an easy, worry free solution. Ipe is one of the only decking options that provides the ability to replace boards.

Why can’t I replace composite or plastic decking boards? These boards fade over time and cannot be refinished. That means, when you replace a composite/plastic board, the old boards won’t ever match the new ones. Ipe naturally varies in color, so the new ones will blend in nicely with the old ones. Sun exposure will also help the new boards match the old ones. Here are some things to keep in mind when considering board replacement,

- The most common dimensions of Ipe Decking are 1×6 and 5/4×6. Less common dimensions like, 1×6+ can be more difficult to replace if they become damaged. Play it safe with the more common profiles.

Consider the fastening method. Some clip designs make it difficult or impossible to access the heads of the screws. Also, plugging an entire deck can make replacing damaged boards more difficult. Learn about different fasteners and their which one is best for your project.

6 . Ipe Wood Can Cup

There’s no denying that Ipe wood can cup. Cupping is the shape a wood board takes on where one side of the board is convex and the opposite side is concave. Typically, with decking, the top/face of the board dips in the center and the sides rise. It is important to understand why boards cup.

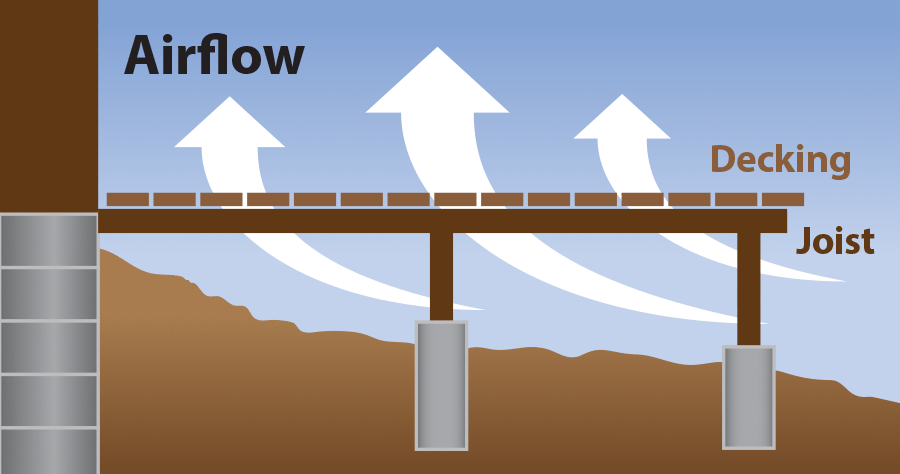

Cupping is always a result of improper ventilation and inadequate moisture equalization. When moisture becomes trapped underneath decking boards and the face of the boards dry, it creates a higher moisture content under the boards than above the boards. This causes the bottom to expand and the top to contract and cup. To prevent this, you’ll want to take these simple precautions,

- Allow space above the ground and beneath the deck. This will allow air to flow all both sides of the board.

- If moisture is not properly draining on the ground under the deck, consider grading the soil and using a waterproof membrane to prevent moisture penetration into the soil.

- Be sure to always leave 1/8th inch gap between the boards. This ensures free air flow on all four sides of the board.

- Don’t close in the sides of the deck, where possible. Leaving the understructure open will allow more airflow.

- Decking boards should never be installed directly on subfloor, concrete, soil or any flat, nonporous surface.

Follow the supplier’s installation guidelines.

What if the conditions are not suitable to achieve suitable airflow and moisture equalization? Some common examples might include, covering a concrete pad without a frame system, a rooftop deck with waterproof membrane, or areas that have a maximum elevation requirement may not allow for suitable airflow. Ipe Deck Tiles can be a perfect solution for those condition. Deck Tiles are manufactured tiles made up of 7-8 smaller Ipe boards. These boards are very resistant to cupping and are a great solution for these types of conditions.

7 . Drying and Checking

Ipe Decking dries and contracts, leaving tiny cracks in the face or at the ends of the boards. These tiny cracks are known as checks. Face checking is a very normal and is very difficult to see. It does not affect the durability, longevity or water-resistant benefits. This checking goes away again once the boards gain moisture and expand. The checking that can be more problematic is called End Checking. End checking occurs at the end of board cuts where moisture can escape more easily. The solution is simple,

- Use End Wax. Most legitimate suppliers of Ipe Decking will include End Wax, by default. If you notice your quote is missing wax, you should ask about it. If you have Ipe, but no wax, you use Anchorseal Wax Emulsion. Simply apply the wax to the ends of boards prior to installation.

8 . Ipe is Too Expensive

The term Brazilian Hardwoods just sounds expensive. Fortunately, as far as reasonable decking options go, it really isn’t. Many customers feel that going with plastic or composite decking is more cost effective than Ipe. While this can be the case, especially with the lowest grades of manufactured decking, it usually isn’t.

- Premium Grade Ipe Decking usually costs between $3.20 and 4.50 per lineal foot.

- Ipe and the Mid-Grade Composites are usually about the same price

- The High-End composites, like Enhance Natural by Trex, are significantly more expensive than Ipe.

- Plastic decking, like Azek, is up to twice as much as Ipe.

- Pressure treated is much cheaper than Ipe, but will last about one quarter of the time. Taking longevity and labor into account, even pressure treated lumber is more expensive than Ipe.

There are also Ipe alternatives that also grow in Brazil and cost less than Ipe. These other species like Cumaru, Tigerwood, Garapa, Purpleheart and Massaranduba are just a beautiful and durable as Ipe.

9 . Ipe is Difficult to Find

This can absolutely be true, especially locally. Depending on where you are in the United States or Canada, Ipe can be difficult or impossible to find, nearby. This has a fairly easy fix,

- Find a reliable source online that will crate and ship it to your jobsite. Always require that your decking is crated. Proper crating will prevent damage by shipping couriers.

- Use Google Maps to help your decision. Find the address of the prospective supplier and look at the satellite photo of the address. Is this a lumber yard and direct importer or is it an off building or home of a broker? Buy direct from the importers. You’ll get better product, support and pricing.

Also, suppliers often run out during Brazil’s wet season. Harvesting Ipe is limited to about 5 months of the year. Torrential rains prevent loggers from working in the other seven months. This means suppliers must plan ahead, the best they can, to prepare inventory for the wet season. Some are effective in doing so, others run out for prolonged periods of time.

- Find a supplier that doesn’t run out. This will help if you require fill-ins or replacements.

10 . Ipe is not Environmentally Conscious

Ipe is one of several Brazilian Hardwoods used for decking, siding and flooring. Of course, much of Brazil is covered in natural rain forests. It’s not unusual for environmentally minded consumers to be put off by the idea that purchasing Ipe will harm our planet’s natural rain forests. Fortunately for everyone, that isn’t the case.

- Ipe is an extremely common tree. It is found from the southern tip of South America to northern Mexico and in the Caribbean Islands.

- There is Legal Ipe and Illegal Ipe. When you purchase legal Ipe, it is a small contribution against lumber poachers.

- Most legally and responsibly harvested Ipe is sourced from the regions Para and Mato Grasso, Brazil.

- According to Ricardo Russo, Brazilian World Wildlife Fund, Ipe and the Lumber industry of Brazil is essential to the people of the Amazon. It is one of the few, low-carbon emitting industries.

- Agriculture, Cattle and Plantation Farms are the largest contributors to deforestation. Brazil’s lumber industry is one of the only commodity industries that increases the value of naturally forested lands. That’s because Ipe is selectively sourced, not clear-cut.

- Oversight and enforcement against illegally sourced Ipe have expanded greatly, in recent decades.

- Always buy Ipe from suppliers who buy directly from Brazil. This will highly decrease the chance that you are supporting illegal supply chains.

- Ipe has no chemicals, is 100% recyclable, reusable, and biodegradable. In comparison, composites are not biodegradable or recyclable which contributes to the plastic pollution, worldwide.

Truth is, as long as you’re purchasing responsibly sourced Ipe, you’re supporting essential, low-carbon emitting jobs in the Amazon and working against illegal timber poachers. Legal Ipe loggers care deeply about the sustainability of Ipe and the surrounding forests. They are also required to follow state specified re-growth regulations. When you buy, legally, you’re supporting these positive attributes. When the demand for legal Ipe falls, illegal log poaching increases.

- This article goes into great detail about how Ipe is sourced, how to find a responsible supplier, and the many advancements in enforcement and sustainability surrounding Ipe harvesting.

In conclusion, Ipe is a great choice for decking. The upfront costs are similar to other options, but it’s longevity and durability makes the long term costs far lower than anything else.

The maintenance for Ipe Decking can either be low or none. Annual oiling will maintain the brown colors otherwise, they’ll turn a beautiful silvery grey and still retain their durability.

Responsibly sourced Ipe helps maintain low-carbon emitting jobs in the Amazon and represents the only 100% natural, biodegradable, recyclable, chemical free and reusable decking materials.