Brazilian Wood Depot

6770 Buford Highway NE

Atlanta, GA 30340

Prices And Availability

SALE!

Ipe 1×6 Decking 4′-7′ Lengths for $5.99 plf!

(While Supplies Last)

New Inventory!

Brown Balau 5/4×6

Champagne Balau 5/4×6

Cumaru Deck Tiles

Red Balau Deck Tiles

Brown Balau 1×6 (Coming Soon!)

If you receive an actionable quote with better prices, from another supplier, please let us know!

If we can also beat competitors’ pricing, we will do that too!

As always, we appreciate your business!

All pricing below is reflective of payment by Credit Card. Save $.10 per linear foot, by paying with cash/check/wire.

This profile is the standard for 12″, 16″ and up to 24″ Joist Spacing!

Premium Grade; S4S; E4E

- Side Grooves for Hidden Fasteners, add $.45 plf (Both Sides or Either Side)

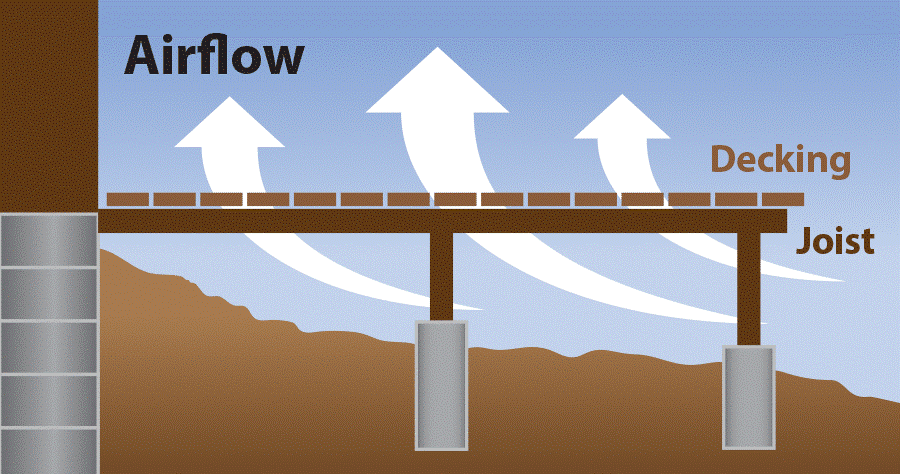

- Bottom Grooves (for Air-Flow Restricted Installs), add $.70 plf (Three Bottom Grooves)

- Side Grooves for Hidden Fasteners, add $.45 plf (Both Sides or Either Side)

- Bottom Grooves (for Air-Flow Restricted Installs), add $.70 plf (Three Bottom Grooves)

- Side Grooves for Hidden Fasteners, add $.45 plf (Both Sides or Either Side)

- Side Grooves for Hidden Fasteners, add $.45 plf (Both Sides or Either Side)

Dimensional Lumber

Premium Grade

Ipe E4E / S4S

2×2 (1.5” x 1.5”)

2×4 (1.5” x 3.5”)

2×6 (1.5” x 5.5”)

4×4 (3.5” x 3.5”)

1×8 (.75” x 7.25”)

1×12 (.75” x 11.125”)

2×4 Handrail

5/4×6 Molded Handrail

Jatoba E4E / S4S

2×4 (1.5” x 3.5”)

2×6 (1.5” x 5.5”)

Premium Grade

Ipe

5″ (Standard 1′-7′)

3.5″ (Plank 6′-14′)

Cumaru (Rosa)

3.5″ (Plank 6′-14′)

Deck Tiles

24″ x 24″

Ipe $50.00 ea

Cumaru $34.00 ea

Red Balau $28.00 ea

Deck tile Connectors $1.95 ea

Deck Tile Pedestals $16.00 each

There are three different Types of Pedestals. All at the same cost,

- SJB-4156 (Screw to Adjust Pedestal) 4.16” Minimum

- SPVC-2656 (Stationary Pedestal) 2.66” Minimum

- SPVC-15 (Stationary Pedestal) 1.5” Minimum

Face-Fastening

- 100 pcs (30 sf) $26.00

- 350 pcs (100 sf) $71.00

- 1750 pcs (500 sf) $310.00

Stainless Steel #8×1.5” (T-15) – Brown Headed (DeckWise)

- 100 pcs (30 sf) $17.20

- 350 pcs (100 sf) $49.00

Smart-Bit (Starborn Ind.)

- Smart-Bit (#7 or #8) w/2 replacement bits $20.00

- Smart-Bit 5 Pc Replacement Bit Pack $16.50

Deck Clips

BWD Deck Clips w/Screws (MagniCoated Aluminum) 100 SF

- These will also come with a a small number of our new, Double Wide clips for butt joints. Learn more about the double wide clips, bwdepot.com/fasteners/#clips

Ipe Clip Extreme (Plastic Coated Stainless Steel) 100 SF

CAMO Hidden/Edge Fastening

CAMO Marksman Pro (3/16″)

CAMO Coated Screws (1 7/8″)

- 100 pcs

- 350 pcs

- 1750 pcs

CAMO Drill Bits (2pcs)

CAMO Drive Bits (2pcs)

Undermount Fastening (DeckMaster by Grabber)

- 250 SF Box

- 25 SF Box

Pro Plug System (Starborn)

- Drill Tool (w/2 replacement bits)

- Replacement Bits 5 pk

Pro Plug Kit (All Species)

- 100 pc

- 350 pc

- 1050 pc

- Ipe Pro Plugs (ONLY Plugs)

Screws GRK SS Trim

- 8x 2 ½”, 100 pc ; 420 pc,

- 8x 2”, 100 pc, ; 600 pc,

We carry the following Steel Railing elements. These panels and accessories are constructed using 100% galvanized and powder coated iron to provide the strongest and most attractive iron railing system on the market. Simple installation, durable, maintenance free, and value pricing make these railing panels the ideal compliment to a Brazilian Hardwood Deck. You dress these panels up with a variety of top rail options, from BWD: 1×6, 1×4, 5/4×6, 2×4, 2×6, 5/4×6 Molded Handrail or *2×4 Molded Handrail

Straight Panels

- 6 ft: 34” x 69.5”

- 8 ft: 34” x 93.5”

Adjustable Panels (for stairs)

- 6 ft: 34” x 72”

- 8 ft: 34” x 93.5”

Mounting Brackets

- Universal Straight (4pk)

- Adjustable Brackets (pk)

- Adjustable brackets MUST be used in conjunction with a Universal Straight Bracket

- Iron Posts- 2” x 2” w/ 4” Base

- 39.5”H

- Rail Post Cap

Messmer’s Products

- Messmer’s Deck Oil; Provides rich, natural glow (Natural/Red/Brown)

- Messmer’s Cleaner and Brightener (Parts A & B, Sold Separately)

Wax Emulsion (Needed on EVERY job!)

- Wax is used on fresh-cut ends. Any cross-grain cut needs a coating of wax to prevent capillary moisture loss, which leads to end-checking.

Ipe Decking, IN STOCK!

BWD delivers locally and professionally ships via LTL and Flatbed to 48 US States. Call us for a quote, today- 770-242-0045.

- About Ipe

- Ipe Decking Photos

- Weather and Color Change Progression

- Benefits of Ipe

- Ipe Decking V.S. Other Decking

- Finishing and Maintenance

- Working with Ipe

- 10 Problems with Ipe and how to Avoid Them

- Real Ipe©

- Ipe Deck Tiles

- Decking Profiles

- Deforestation, Sustainability, and Illegal logging

- Architect and Design Library

- Ipe FAQs

- Quotes and Samples

- Shipping and Delivery

- Ipe Videos

What is Ipe Wood?

Ipe (pronounced EE-pay) is world-renowned for its superior characteristics and properties. Ipe is one of the hardest woods in the world which lends to its incredible durability and longevity. It is also naturally resistant to insect attack, mold, rot, fire and decay. The color of Ipe heartwood is a rich brown with red and amber hues and varies considerably from board to board. Ipe wood decking grain is extremely dense and tight with visible cathedral arches and contrasting grain patterns throughout. Due to the wood’s fine texture and interlocking grain, Ipe offers superior slip resistance.

Ipe decking is incredibly versatile. Its durability makes it a natural choice for commercial projects, such as high-traffic, large-scale beach piers or boardwalks, or even public benches. However, its beauty, strength and low needs for maintenance also make it a leading option for residential decking.

Ipe is considered the highest quality, best natural wood decking material on the market today. It is also one of the most popular species for decking we stock at Brazilian Wood Depot. On this page, you’ll learn more about Ipe decking, the benefits it provides and other useful information to help get you started.

Ipe Decking Photos

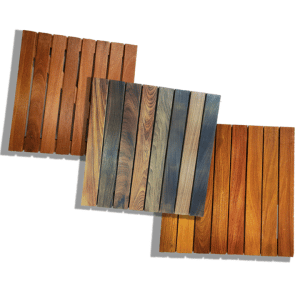

Weather Color Change Progression

Sunlight has a bleaching effect on nearly everything it comes into contact with. Hardwood decking boards are no exception. The purpose of this demonstration is to show the sun’s effect on Brazilian Hardwood Decking and what to expect from reoiling. These boards were left on the roof of our building for 12 weeks to simulate a deck with heavy sunlight and weather exposure. All the boards began with one coat of Messmer’s UV Plus (Natural). After the 12th week, another coat was applied to half of each board.

The video to the right includes more details about how I did the demonstration and other interesting findings.

Fresh Deck Boards

Garapa

Tigerwood

Purpleheart

Massaranduba

Cumaru

Ipe

Fresh Decking Boards Before Sunlight Exposure Finished with One Coat Messmer’s UV Plus Natural

3 Weeks Exposure

Ipe

Cumaru

Massaranduba

Purpleheart

Tigerwood

Garapa

Three weeks of full sunlight and weather exposure.

6 Weeks Exposure

Ipe

Cumaru

Massaranduba

Purpleheart

Tigerwood

Garapa

Six weeks of full sunlight and weather exposure.

9 Weeks Exposure

Ipe

Cumaru

Massaranduba

Purpleheart

Tigerwood

Garapa

Nine weeks of full sunlight and weather exposure. Boards are now almost grey, but certainly have lost their original richness, in tone.

12 Weeks Exposure & ReOiled

Ipe

Cumaru

Massaranduba

Purpleheart

Tigerwood

Garapa

At 12 weeks, the boards are fairly uniform in their grey color. I applied oil to the top half of these boards so you can see the difference between the washed-out 12-week appearance and the newly oiled appearance.

Benefits of Ipe Decking

Ipe decking, also known as Brazilian Walnut, has a number of qualities that make it stand out as the superior outdoor construction material.

- All Natural- Unlike composite decking, which is a combination of wood pulp and plastic, a non-recyclable material that pollutes our planet and pressure treated or reclaimed lumber that is loaded with toxic chemicals known to harm surrounding plant and animal life, Ipe is 100% natural. It is ideal for repurposing, bio-degradable and does not create any biproducts that can harm the environment. No chemicals or plastics whatsoever, just 100% real wood. That’s why we say, “Go Natural!”

- Hardness- Ipe is among the 10 hardest woods in the world with a Janka Hardness rating of 3,680; compare that to Oak, at about 1,200. Many compare Ipe’s hardness and density to concrete. This extreme hardness lends to its dimensional stability, long lifespan, and natural weatherproof properties. Pressure treated wood is known for substantial expansion and contraction with seasonal changes. This process destroys the cell structures from the center of the boards, outwards. It also increases the rate of decay. This movement is also responsible for creating raised wood grain that can be painful to walk on without shoes. Raised grain is a common problem with pressure treated woods but does not occur with tropical hardwoods like Ipe. Composite and plastic decking will also expand and contract significantly over time which compromises the rigidity. This eventually leads to boards drooping between the joists. Ipe, being so hard, will expand and contract some, but very little. Minimal movement is one key element to Ipe’s incredible longevity.

- Longevity- Ipe is renowned for its ability to last many decades even in extreme weather conditions. Density and hardness, as discussed above, plays a large role in that. Natural resistance to water penetration and rot/decay also contributes to its longevity. The forests, from which they evolved, experience 100-400 inches of rain per year. That is up to 8-10 times more than anywhere in the United States. Evolutionary responses to this heavy rainfall have made this wood naturally resistant to water penetration, mold, rot and decay.

Board Replacement- Many people fail to consider how board replacement can be a HUGE obstacle with alternative deck materials like PT or composite. Let’s say you drop the hot contents of a grill on your deck and it damages the boards beyond repair. Unfortunately, if you don’t have an Ipe or tropical hardwood deck, you’re in for a rude awakening. When you replace a PT or Composite deck board, it will stand out from the others, dramatically. These materials are all very consistent and continue fading over time. So, the new boards will ALWAYS stand out from the others. You are left with a deck that has very obvious patchwork. Tropical hardwoods vary from board to board, so replacing boards is no big deal. They may stand out from the others for a couple of months, but before long no one will be able to tell the new boards from the original ones. This benefit is specific to real, natural woods. Board replacement is also a common problem with prefinished and engineered wood flooring.

- Insect Resistance- Ipe, and other tropical hardwoods, are naturally insect resistant. Domestic lumber is treated with chemicals to deter wood boring insects. Ipe evolved in forests with insects much more proficient at wood-boring than their North American counterparts. Very few insects in their natural habitat are capable of infiltrating their tough wood fibers and certainly, the domestic insects of the United States are no match. This is true for most tropical hardwoods.

- Fire Resistance- For many states in southwestern United States, fires are a large factor driving construction material decision making. This also holds true for large commercial projects in urban areas. Ipe is the most flame-resistant decking material, hands down. Ipe is one of the only materials, aside from steel and concrete, that regularly receives an A Class rating from engineering rating organizations. Plastic, composite and pressure treated lumber typically receive the lowest flame spread ratings C Class. Watch Matt Risinger’s YouTube video demonstrating Ipe’s incredible resistance to fire.

- Forest Stewardship- Ipe is sourced from the tropical forests of South America, Brazil in particular. Concerns with harvesting Ipe from the “lungs of our planet” are well warranted. The truth is, Brazil’s hardwood timber industry may be the forests best protection from clear-cut uses like Cattle and Agriculture. When Ipe is harvested and regrown in its natural habitat, that habitat is protected by both he organization that replanted and the local or federal government. Without responsible forestry management, forest lands are more likely to be cleared for grazing cattle and planting crops. Each purchase of Ipe, or other tropical hardwood, from conscientious hardwood dealers like Brazilian Wood Depot contributes to the value of naturally forested lands.

- Cost- Contrary to popular belief, Ipe is not more expensive than the alternatives. The opposite, in fact. Pressure treated lumber is considered to last about 5-7 years before boards begin to deteriorate and rot. Plastic and composite boards will typically begin to fade and deteriorate within a few years. A composite deck is unattractive and nearly unusable after about 8 years. Alternatively, Ipe is known to last from 40- 75 years, depending on the environmental conditions. When you consider the cost of replacing pressure treated or composite boards through the life of just one installation of Ipe, Ipe is far, far more cost effective. The front-end cost of Ipe decking is generally the same as the mid-grade composites and lower than the high-end composites. Pressure treated lumber is cheaper than Ipe, but you’ll replace the PT boards 5 times in the life of one Ipe deck. So, is Ipe the most cost-effective decking? Yes, often in the short-term, but always in the long-term.

Ipe Decking V.S. Other Decking

| Real Ipe | CCA-Treated Pine | Composite Decking | |

|---|---|---|---|

| Type | Hardwood | Softwood | Plastic |

| Maintenance | Low | High | Low |

| Decay Resistance | High | Varies | Varies |

| Termite Resistance | High | Varies | Varies |

| Strength | High | Medium | Low |

| Movement in Service | Low | High | High |

| Fire Rating Class | High | Varies | Low |

| Weight per Cu Ft. | 69 lbs. | 35 lbs. | 60-64 lbs. |

| Bending Strength | 25,400 psi | 9,900-14,500 psi | 1,423-4,500 psi |

| Shear Strength | 2,060 | 1,370 | 561-1,010 |

| Hardness | 3,680 | 690 | 940-1,390 |

How does Ipe decking compare to Composite decking? Visit our Composite Comparison page.

Compare Ipe Decking to Plastic/Composite Decking

Ipe is one of the hardest, commercially available, woods in the world. With a Janka hardness rating of 3680, Ipe can withstand the most extreme elements and commercial wear and tear. Currently, there are no decking options that compare to Ipe’s many benefits. Plastic Decking is one alternative, but it has many downsides…

Read More

To start with the obvious, Trex and other Plastic or Composite Decking alternatives offer no natural features. Plastic or Composite options are either all grey or all beige or somewhere in between. All the boards will be exactly the same color with the exact same printed grains. Ipe Decking and other Brazilian Hardwood Decking offer only real, natural wood colors with real, natural grains. This means a beautiful variation of boards with each a unique grain pattern on every deck. The next downside to Plastic or Composite Decks is their inability to be repaired. If a board(s) gets damaged, scratched, stained or broken, the damaged piece cannot be fixed because Plastic and Composite Decking fades with time and exposure to the elements. If you were to replace one board on a Plastic Deck or Composite Deck, it would stick out, very obviously, from the other boards. The new boards would be the ‘manufactured’ color, while the others would be faded. This disparity will never even out. Moreover, Plastic and Composite Decking cannot be pressure washed or sanded to restore color. You are never really able to bring a Plastic or Composite Deck back to its original condition without replacing all of the boards.

Ipe Decks, on the other hand, can easily be brought back to their original condition. Keeping with the scenario outlined above, if a board on an Ipe Deck is damaged and needs to be replaced, all you would need to do is get a replacement board to put in its place. Because the color of Ipe varies from board to board, it would not stand out from the other boards at all. It’s natural variability in color lends to its advantage if a board ever needs to be replaced. Alternatively, if the board was scratched or stained, one merely needs to sand the surface of the stained board(s) and reapply the UV oil to bring them back to their original condition. Ipe Decks last forever not only because of their resilience to rot and decay, but also because the boards CAN be repaired, a quality not found in any other decking material. Another aspect that many people fail to consider before installing a deck is Heat Dispersion and Flammability. Wood is the best decking material for disbursing heat making the deck cooler to walk on and Ipe also has a similar fire rating to concrete. Basically, it’s a naturally non-combustible material. Plastic and composite decking is very hot and can create a fire hazard if installed outside a UV reflecting window.

Finally, the last major downfall of Plastic and Composite decks, sagging and drooping. The chemical combinations for Plastic and Composite decking options have changed over the years in an attempt to avoid problems like, insects, mold, and rot. Unfortunately, one problem that has yet to be tackled by even the most advanced Plastic or Composite Decks is sagging and drooping. Sagging and drooping refers to the pendulous deformation of deck boards between the joists. As far as longevity goes, this is the main problem for Plastic and Composite Decks. After several years, the chemical components in the decks breakdown which compromises the rigidity of the boards. It can compromise the strength in such a dramatic manner that the boards themselves loose their ‘straightness’ and droop between the joists. This is an extremely well-known problem for Plastic and Composite decks that has never been successfully addressed. Ipe Decking is 100% natural. There are no non-organic chemicals to breakdown. Ipe’s high density and hardness that lends to its’ incredible dimensional stability is why Ipe decks outperform Plastic and Composite decks in regard to longevity, 10 to 1. These are just a few reasons that Ipe Decks are the preferred choice over Plastic and Composite Decks. All considered, there really is no comparison between an Ipe Deck and a Plastic or Composite Deck.

Contact us with any questions on comparisons of Ipe and composite decking.

Finishing and Maintenance

To oil or not to oil, that is the question. With Ipe or any other tropical hardwood from Brazilian Wood Depot, you have basically two options when it comes to maintaining your deck, but you don’t have to stick with either one. You can either skip the oiling and let the boards go a beautiful silvery-grey or use oil to maintain the natural brown colors. Below, I’ll go into what both options mean for you and your deck.

First, what happens when you do not use a UV protectant oil? The purpose of UV Oil is to protect the wood from ultraviolet rays emitted by the sun. These rays eventually ‘bleach’ the boards of their natural brown color. What’s left, after significant sunlight exposure, is a beautiful silvery-grey surface that has a natural ‘reclaimed’ appearance.

Typically, the board colors become more consistent with more time left in the sun without UV protection. The ‘greying’ process will not affect the structural integrity, lifespan, or water resistance of the boards. Let’s say, when the deck was originally installed, you didn’t apply the oil because you wanted the deck to turn grey. You can always bring Ipe back to its brown condition. It may require a cleaning before oiling, just follow directions in the video, above.

FULL Cleaning and Oiling Instructions PDF

Choosing to finish your deck or leave it unfinished is a personal choice and you can’t go wrong either way. Brazilian Wood Depot is here to help you decide whether or not to stain your Ipe deck. We will be happy to discuss your options.

Working with Ipe

Working with Ipe

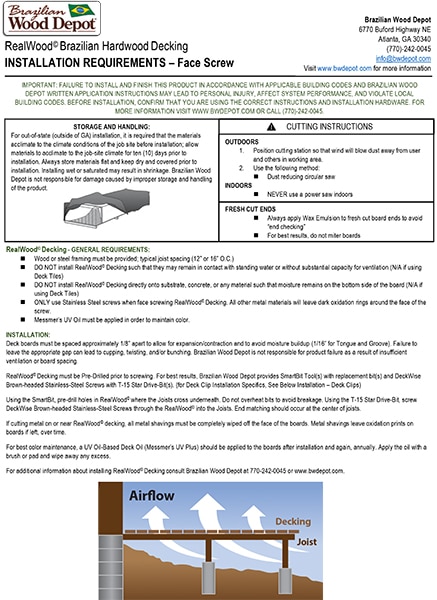

Storage and Handling

For out-of-state (outside of GA) installation, it is required that the materials acclimate to the climate conditions of the job site before installation; allow materials to acclimate to the job-site climate for ten (10) days prior to installation. Utilizing spacers or stickers between boards to allow air movement and natural drying also aids the acclimation process. Always store materials flat and keep dry and covered prior to installation. Installing wet or saturated boards may result in shrinkage. Refer to the Installation page, for more information.

When designing your deck plan, you must provide for adequate ventilation to assure long term stability and avoid cupping. Proper air ventilation allows air to flow in from outside the deck area and under the joists to evaporate moisture. Gently sloping the soil under the deck away from the house and covering the soil with plastic is recommended for any type of deck installation. Allow a 1/8″ gap between standard deck boards for drainage and airflow. More detailed instructions can be found on the Installation Page. There are a number of different fastening methods; Face Screws, Kerf and Clips, Grabber Bars, Camo, or ProPlug. For a more detailed description of these methods visit the Fasteners Page.

10 Problems with IPE And How to Avoid Them

This is a blog article we wrote about common misconceptions and avoidable problems, with Ipe Decking. This is a great resource for first-timers and those with questions or concerns. You can find the full article at, https://www.bwdepot.com/10-ipe-problems/. Or use the navigation table below to skip directly to different sections of the article.

Real IpeTM

supplied by Brazilian Wood Depot.

At Brazilian Wood Depot, we also place an emphasis on the proper shipment of our lumber, to ensure that your Ipe decking material arrives in the quality and excellent condition you deserve, preventing costly setbacks, stresses and inconveniences.

With special wood crates for shipping and transportation, low overhead costs and large number of shipments, we can pass on great savings to you, while ensuring a smooth delivery process. We deliver Ipe across the entire United States.

Ultimately, with Real Ipe for your home, you’ll be receiving a beautiful, hassle-free and long-lasting choice that will make your deck the envy of the neighborhood, but also simply a wise investment.

Call 770-242-0045 for any other information or for specific pricing on Ipe.

Ipe Deck Tiles

You can transform your garden, patio, roof or balcony, with these easily installed ipe deck tiles. They are also used in large commercial areas like bars, restaurants, exhibition areas and office buildings with heavy pedestrian traffic.

Deck Tiles are also a perfect solution for area coverage that cannot achieve moisture equalization. Consult a Brazilian Wood Depot representative to determine if Ipe Deck Tiles are right for your next project.

Ipe Lumber Profiles

Brazilian Wood Depot also carries a number of different profiles to accent different features of your deck like stair risers, balusters, railing sections, handrails, facia, posts, etc… Refer to the Profiles and Dimensions document for profile availabilities.

Ipe: Deforestation, Sustainability and Illegal Logging

You may be familiar with Ipe as the “King of Woods.” A species with almost unbelievable characteristics- natural

resistance to rot, insect attack, and mold with density and hardness comparable to concrete. These features give Ipe and other tropical hardwoods the ability to outlast pretty much everything while providing unrivaled beauty and character. All of this is true. Ipe has been a staple in the decking, flooring, siding and furniture industries for many years for these reasons. Furthermore, in recent years, the prices of tropical hardwoods like Ipe, Cumaru, Purpleheart, Tigerwood, Massaranduba and Garapa will beat out even the mid-tier composite decking and siding alternatives. If that were the end of the story, these tropical hardwoods would be the market leaders for outdoor construction, hands down. Unfortunately, some narratives paint a darker picture of Ipe that is both misleading and endangers our native tropical forests.

Architect and Design Resources

We are very proud to announce that Brazilian Wood Depot, with the help of CADdetails.com, has made specifying Brazilian Hardwood Decking and Siding much easier!

Incorporate Brazilian Hardwood Decking and Siding products into your

plans quickly and easily by downloading our design files from

CADdetails.com. CADdetails is specifically designed for architect and

design professionals aimed at getting manufacturer-specific product

information for working plans.

On our Microsite, you’ll find CADs, Specifications, BIMs, 3D Models, and other design-related media for Brazilian Wood Depot and BWD

products. This database will continue to grow in the coming weeks

and months.

Click here to visit our Architect and Design Library at CADdetails.com

FAQ’s

How do I refinish my deck?

Click here to read our Blog post: Cleaning and Refinishing Hardwood Decking.

You can also find an in-depth video on our Videos page, Ipe Deck Maintenance Video. This video applies to ALL species of Brazilian Hardwoods.

How do I clean my deck?

Click here to read our Blog post: Cleaning and Refinishing Hardwood Decking.

You can also find an in-depth video on our Videos page, Ipe Deck Maintenance Video. This video applies to ALL species of Brazilian Hardwoods.

What is the best deck finish for hardwoods?

Messmer’s. Brazilian Wood Depot stocks this finish. Click here to read our Blog post: Cleaning and Refinishing Hardwood Decking.

You can also find an in-depth video on our Videos page, Ipe Deck Maintenance Video. This video applies to ALL species of Brazilian Hardwoods.”

Should I pressure wash my deck before finishing it?

NO. Pressure washing it will leave streaks, potentially tear up the surface of the wood and will not clean as deeply as the cleaner.

Where does Brazilian Wood Depot Ship?

We ship to all areas of the US.

For additional FAQ’s visit our FAQ’s Tab.

Quotes and Samples

Brazilian Wood Depot is here to help! We pride ourselves on superior customer support and turning around samples, quotes, and orders faster than anyone else. Please call us for samples or quotes, 770-242-0045.

Generally, all we need to get started on pricing your deck is the answer to a few, basic questions. We can help you answer these questions too:

- What species? With Six incredible Brazilian Hardwood species, deciding on just one can be a difficult I’d recommend familiarizing yourself with the different options on the Decking Tab or this Video.

- How will you fasten the boards? Whether you are using face screws, hidden clips, grabber bars, or the Camo system, we’ve got you The decision is yours to make and your installer can also help guide this decision based on their preferences. Visit the Accessories Tab for more information on fastening methods.

- What are the basic dimensions of the deck and the joist spacing? Obviously, we’ll need to know the size of the

deck to get things started. Joist spacing information allows us to quote accurate fastening quantities.

- Additional Deck Features? You don’t need to know all the intricate details of your deck design to get a basic quote, but if you do have the information it can help make the quote more Additional features would include; steps, risers, posts, railing sections, handrail, and facia.

This is all we need to get you started on pricing your new deck. Again, we’re here to help you make the best decisions

for your deck. You can reach us anytime at, 770-242-0045.

Shipping and Delivery

Brazilian Wood Depot has the most robust shipping process, IN THE INDUSTRY! There’s no debate about that and we know it! Every LTL shipment is fully crated to prevent damages.

We are now also offering LIVE 4G GPS TRACKING on LTL shipments! We are the only distributors in the industry that offer this service! You’re going to love it!

Read more about our robust shipping process, www.bwdepot.com/shipping

Board Replacement- Many people fail to consider how board replacement can be a HUGE obstacle with alternative deck materials like PT or composite. Let’s say you drop the hot contents of a grill on your deck and it damages the boards beyond repair. Unfortunately, if you don’t have an Ipe or tropical hardwood deck, you’re in for a rude awakening. When you replace a PT or Composite deck board, it will stand out from the others, dramatically. These materials are all very consistent and continue fading over time. So, the new boards will ALWAYS stand out from the others. You are left with a deck that has very obvious patchwork. Tropical hardwoods vary from board to board, so replacing boards is no big deal. They may stand out from the others for a couple of months, but before long no one will be able to tell the new boards from the original ones. This benefit is specific to real, natural woods. Board replacement is also a common problem with prefinished and engineered wood flooring.

Board Replacement- Many people fail to consider how board replacement can be a HUGE obstacle with alternative deck materials like PT or composite. Let’s say you drop the hot contents of a grill on your deck and it damages the boards beyond repair. Unfortunately, if you don’t have an Ipe or tropical hardwood deck, you’re in for a rude awakening. When you replace a PT or Composite deck board, it will stand out from the others, dramatically. These materials are all very consistent and continue fading over time. So, the new boards will ALWAYS stand out from the others. You are left with a deck that has very obvious patchwork. Tropical hardwoods vary from board to board, so replacing boards is no big deal. They may stand out from the others for a couple of months, but before long no one will be able to tell the new boards from the original ones. This benefit is specific to real, natural woods. Board replacement is also a common problem with prefinished and engineered wood flooring. Working with Ipe

Working with Ipe